(www.MaritimeCyprus.com) The ocean transportation of liquid cargoes, such as petroleum, petrochemicals and pressurized products, is an inherently highly hazardous process. Marine accidents in this field can result in casualty, serious damage to the environment as well as significant economic losses.

With tanker ownership having moved from oil and chemical companies to independent ship owners in the 1980s, public concerns on serious tanker accidents were raised. To evaluate the risks of a vessel, the Oil Companies International Marine Forum (OCIMF) developed the Ship Inspection Report Programme (SIRE), which later became an obligatory step in chartering so substandard oil tankers can be eliminated.

Essentially, SIRE is a comprehensive database of up-to-date information about the vessels, proving that they can transport cargoes safely, responsibly, and competitively. Today, SIRE covers the following ship categories: tankers, chemical tankers, LPG ships, LNG ships and combination ships (Category 1 and 2 based on tonnage) as well as offshore barges, inland barges (manned and unmanned) and integrated barges (Category 3).

As the industry continues to evolve, OCIMF has decided in 2017 to develop SIRE 2.0, an enhanced and risk-based vessel inspection programme that will supersede the existing SIRE programme. SIRE 2.0 is expected to provide more accurate information to enable OCIMF members and programme recipients to make judgments on the quality and the likely future performance of a vessel. It is projected to become operational in Q4 2022.

How will SIRE 2.0 work?

What documents are needed?

In the present SIRE system, there are two documents that must be provided by the operator prior to inspection: An up to date harmonized vessel particulars questionnaire (HVPQ) and a crew matrix. In SIRE 2.0, there are four documents needed:

- Harmonized vessel particulars questionnaire (HVPQ)

- Pre-inspection questionnaire: This is expected to be an online questionnaire completed by the vessel operator providing information about the vessel and supplementing HVPQ. This might include crew matrix and details of internal and external audits carried out on the vessel such as ISM audit, navigation audit, TSI report, etc.

- Certificates: The operator will be required to upload copies of all the vessels’ certificates and keep them up to update, such as after class surveys.

- Photographs: A representative and standardized set of photographs of the vessel must be uploaded. It needs to be refreshed at around 6 months intervals or when any materials change in the vessel.

How will the new question set be graded?

A bespoke, risk-based vessel inspection questionnaire will be generated using bow-tie methodology. Questions will cover these four key areas:

- Core: A minimum question set required to meet the fundamental assessment criteria of the vessel type. These questions are related to significant risks on board a vessel as defined by OCIMF.

- Rotational: An algorithm will assign the non-core questions embedded into the inspection program. These questions may be allocated over several inspections of the same vessel but the order can’t be predicted.

- Conditional: Vessel-specific questions based on available data on the vessel, its operator, or the ship type such as an aspect of the vessel’s operational history.

- Campaign: Time-limited questions covering an area of specific focus in response to incidents or an industry trend. It might be similar to the campaigns used by port state control organizations targeting specific areas of a vessel and its management for a

What about the human element?

A core element of SIRE 2.0 takes a human-centered approach which will provide a defined process to uncover systemic issues that might lead to risks. The human-centered approach will take into consideration the physical, psychological, and social factors that affect human interaction with equipment, process and with other people.

This is achieved by assessing Performance Influencing Factors (PIF). Inspectors will be prepared with a human response toolkit. For each question which is associated with Performance Influencing Factors, the inspector will be asked to provide objective responses to nine areas. These areas cover a variety of factors relating to human errors such as accessibility and usefulness of procedures, human-machine interfaces or the opportunity to learn or practice.

What is the technology involved?

Instead of a static questionnaire with yes/no answers, SIRE 2.0 inspections will be conducted in digital format, in real-time, with inspectors completing a Compiled Vessel Inspection Questionnaire (CVIQ) using a tablet device. This aims to improve the overall quality of the inspection report and also increase the assurance of data. The tablet system will also record all interactions such as auto-logging of start and finish times and auto-submission of inspection reports via inbuilt GPS tracking.

How will the inspection be conducted then?

The inspector will carry out a document review prior to boarding by checking all the certificates and information given in the PIQ, certificates, etc.

The time for onboard inspection is fixed at eight hours. All the questions are allocated a period of time for the inspector to review the item in question and write their answer. The format of the CVIQ will be entirely different to the present VIQ7 format. It will be compiled specifically for that ship on that occasion for that inspection. Human and process deficiencies may be linked to TMSA KPIs. The onboard document review will be a brief sample review to confirm the certificates uploaded are correct.

The inspector must validate the photos posted by the operator and take their own photos, particularly for observations. Also if an operator's photograph is not truly representative, then the inspector may take a photo of the same scene. All questions must be answered during the course of the inspection such that the report is largely complete before the inspector leaves the vessel. The time period for the operator responses to the observations may be reduced from 14 calendar days to seven working days.

Easing into SIRE 2.0

Inspection programs are designed to lower risks. However, many inspection regimes require extensive preparations and take a long time, which causes various headaches to tanker operators. According to research, the average price of the inspection is at least 33,600 USD per oil tanker, and the inspection workload has become an additional burden to crews.

The big overhaul in the SIRE regime will require additional adaptation in the vessel’s technical operations. The requirements have become more specific, which means the normal technical operations of the vessels need to be adjusted.

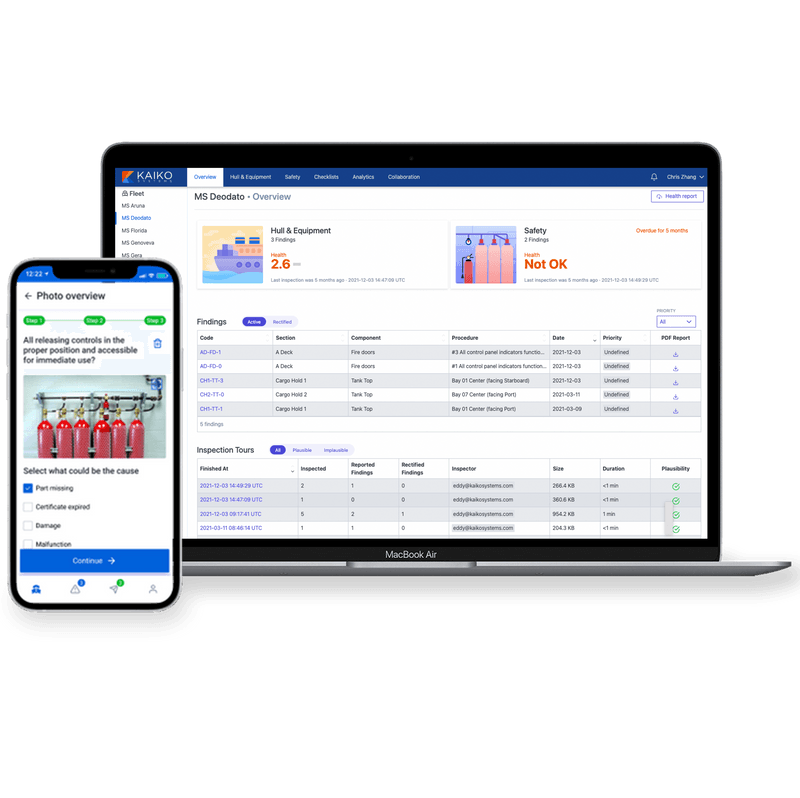

In the meanwhile, with SIRE going mobile, it also indicates that inspection is entering a mobile-based era. It is therefore recommended that tanker operators start to evaluate mobile-based inspection solutions that are flexible, accurate, and able to increase efficiency. In the case of Kaiko Systems, the mobile app not only guides crews to conduct inspections but also allows them to plan, conduct, and upload inspections in one platform. This ensures that standards from SIRE 2.0 can be met while saving crews 50% of time spent on inspections.

In addition, the system can automatically verify and structure the data into a vessel health report. The dynamic analysis can reveal risks to the shore team in clicks and allows them to manage maintenance proactively. Kaiko Systems also brings great flexibility. With Kaiko Systems, intervals can be adjusted easily and reports can be customized. Thus, inspections like SIRE 2.0, Pre-PSC Inspections, routine inspections, and many more can be conducted with accuracy and efficiency.